Quick Stock/Price Check

Quick Order

Request Samples

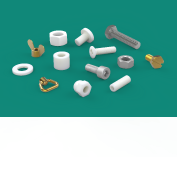

Are you looking for samples for your project? We have thousands of Nylon, Aluminium, Titanium & Brass Products In Stock.

This site works better with javascript enabled.

This site requires sesison-cookies. You can enable this through your browser. The session-cookie is removed from your computer when you close your browser.

Screws & Washers

Threaded Inserts

Quick Release Pins

Access Hardware

Teknipart Ltd

Teknipart Ltd

Teknipart Ltd

Teknipart Ltd